2) CaCO 3 filler particles' long axes in molded specimen measure from <1 to 7 μm. Glass fiber reinforcement usually ranges from 5 to 30 mass% with nominal lengths of 3.2 to 12.7 mm (1/8 to 1/2 in), 1) and nominal diameters ~14 μm. GFRP-BMCs are 3-phase composite systems typically composed of short glass fiber, polymer, and contain a high mass% of powder filler such as CaCO 3.

Injection molding is commonly used for BMC as it can be easily produced with high productivity for mass production of large and small components with a smooth and attractive surface finish. BMCs have excellent flow characteristics that make them well suited for parts requiring precise dimensions and detail. For mass production, BMCs are lower production cost than GFRP long fiber layup possessing easier production than prepreg long fiber production methods.

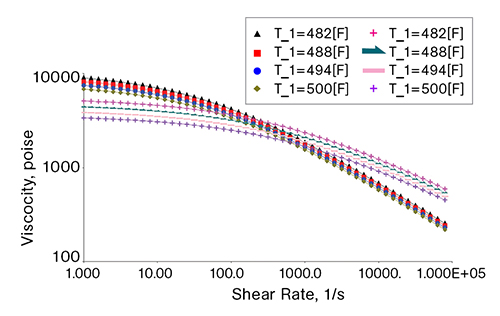

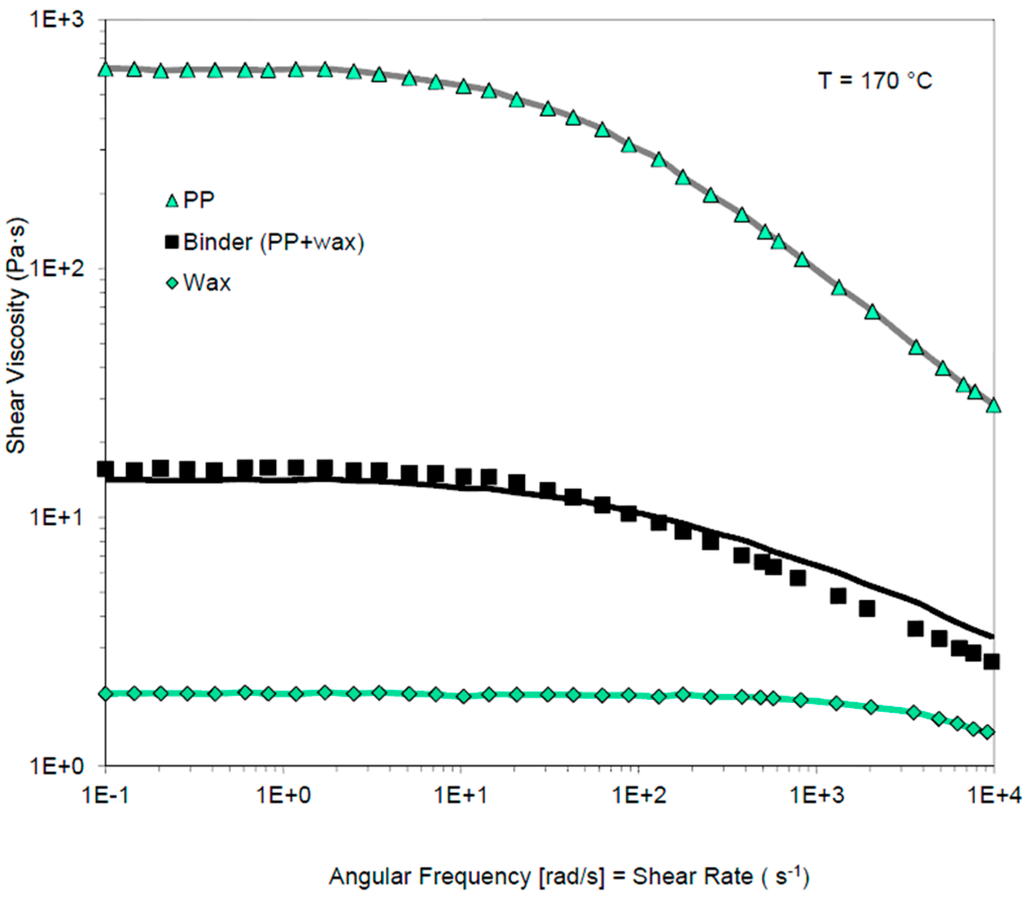

They are lighter and have a higher strength/density ratio than steel and Al. Short glass fiber BMCs are lower cost than steel, Al and Mg when making parts in high quantity. BMCs offer precise dimensional control, flame and tack resistance, high dielectric strength, corrosion and stain resistance, and color stability. Glass fiber reinforced polymer (GFRP) bulk molded compounds (BMCs) have had a wide market for aerospace, automotive parts, housing for electrical wiring, corrosion-resistant needs, and day-to-day articles. This was without buying new equipment, using the existing injection molding machine to save cost. Moreover, the Mooney-Rabinowitsch calculation is found to be a decent predictor for shear rates across specimen thickness and at mold walls measured from the mapping. Based on the viscosity measurements a new “mold filling” model is constructed with physical meaning to predict needed injection molding parameters pressure (d P), shot time ( t s) and shot weight ( m s) for various size dog-bone specimens varying length ( L tot), gauge length ( L B), width ( w) and thickness ( th) for the optimized formulation. The mapping was from 0.44 mm fiber formulation molded sample exhibiting ~60, ~40 and 20% higher tensile strength, strain, and modulus, respectively than commercially used ( l fiber = 6.4 mm). Experimental viscosity measurements (50 to 100 Pas at mold walls, T = 273 to 373 K) of an injection-molded highly-filled glass fiber reinforced polyester bulk molding compound (GFRP-BMC) whose fiber length ( l fiber = 0.44 mm) was optimized for tensile mechanical strength agreed well with that previously calculated by Navier-Stokes equation from fiber orientation mapping.

0 kommentar(er)

0 kommentar(er)